Most stock cylinder heads come with press-in studs as standard. These are typically sufficient for everyday driving and moderate performance applications. However, for high-performance engines, especially those with high lift cams or high RPMs, upgrading to screw-in studs is often recommended. Screw-in studs provide a more secure and durable connection, reducing the risk of stud pull-out under extreme conditions.

Stud boss facers play a crucial role in the realm of cylinder heads and valvetrains.

What are Stud Boss Facers?

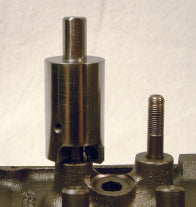

- Imagine you're peeking under the hood of an engine. You spot those stout metal studs poking out from the cylinder head, holding the rocker arms in place. Those studs have a boss - the raised area around them.

- Sometimes these bosses need a makeover. They might be too tall, uneven, corroded or flexed.

Why are they necessary?

- Screw-in rocker studs: They are threaded and can be adjusted for precise rocker arm geometry, but they demand a well-prepped boss to sit on.

- Stability and alignment: The stud boss needs to be flat and at the right height. If it's wonky, your rocker arms won't work harmoniously with the valves.

- High lift cams and stout springs: When you are pushing the limits with aggressive cams and beefy springs, the stud boss needs to be solid, or it might crack under pressure.

How to give the Stud Boss a makeover?

- Remove the cylinder heads.

- Use Goodson's Stud Boss Facer (SBF-5587) tool to cut most of the boss off to relieve the pressure. The stud will then come out without breaking the boss.

- You will end up with a thin "post" that needs a gentle whack with a chisel to remove it.

- Countersink the hole to help start the tap.

- Repeat this process for all the studs.