Did you know that Goodson sells Brake Lathe Cutting Tips? And did you know we offer them in 3 different grades?

That's right! Goodson offers brake lathe cutting tips in 3 grades - Standard Solid Carbide, Honed Edge Solid Carbide and Titanium Coated Solid Carbide.

Here's a quick run-down:

Standard Solid Carbide

These brake lathe cutting tips are parallel ground for resurfacing cast iron brake drums and rotors. They are available for most brake lathes with positive or negative rake as well as round cutter tips.

Honed Edge Solid Carbide

These brake lathe tips are a step up from the standard grade carbide. They are parallel and peripheral ground to create a honed edge to deliver a better finish on cast iron and composite rotors. These tips are ideal when there's a lot of rust on the rotors you're turning.

Titanium Coated Solid Carbide

Top of the line, titanium coated carbide tips are also parallel and peripheral ground to create an exceptional edge. The titanium coated is designed for ultimate performance on cast iron and composite rotors. We do NOT recommend using titanium coated tips on rusty surfaces as this is likely to chip the titanium coating.

For more on the differences between standard, honed-edge and titanium coated cutting tips, check out our Brake Lathe Cutting Tip Test Results article.

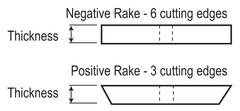

Let's talk a little about the rake of the brake lathe tip. First off, what do we mean by rake? Rake is the angle of cutting face relative to horizontal. Sounds a little confusing so let's look at a diagram (right).

Let's talk a little about the rake of the brake lathe tip. First off, what do we mean by rake? Rake is the angle of cutting face relative to horizontal. Sounds a little confusing so let's look at a diagram (right).

The rake of the brake lathe cutting tip (or bit) that you need is determined by the type of machine you have.

Most brake lathe cutting tips are triangle shaped with a hole in the middle where they attach to the brake lathe tip holder. There are, however, solid triangular tips, rectangular tips and round tips.

As you can see in the diagram above, negative rake cutting tips have 6 cutting edges and positive rake cutting tips have 3 cutting edges.

But what about round cutting tips? Depending on the depth of the cut on the rotor they can have up to 20 cutting edges.

You can achieve 10 cutting edges on a round cutting tip by take a cut .030" deep on the rotor.

Reduce the cutting depth on the rotor to .020" to increase the cutting edges from 10 to 13.

To achieve 20 cutting edges on a round cutting tip, decrease the cutting depth to .010".

As always, if you have additional questions about this or any technical topic, contact the Goodson Tech Services Department by phone (1-800-533-8010) or email.